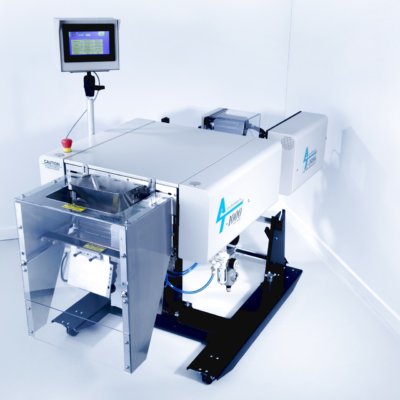

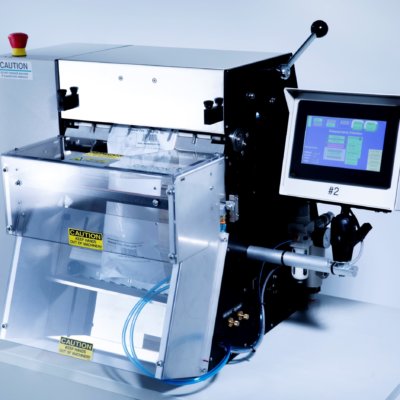

The table machine T-275 packs even faster than the T-200 because the automation is improved compared to the T-200. The bags are no longer pulled by hand into the loading and sealing position, but this process is done by the machine itself. All you need to do is put your products in the bag opened by a stream of air and use the foot or safety switch to seal and blow off to activate the bag from the bag chain. Finished.

The cyclical runs are digitally controlled. The throughput counter and the waiting time for filling before welding are set and automatically saved when the machine is switched off so that they can be called up again in the next packaging series.

The digital control panel shows “Auto” (set speed for the automatic cycle) or “Manual” (activated by pressing a button or pressing the foot pedal), it contains a cycle counter that shows the total number of filled and sealed bags, and It shows the set data as well as the welding time, filling time delay and welding point. The settings are saved when the power is switched off and can be called up later.

Standard features:

- Touch screen panel for the operator

- Solid, constant heat-sealing bar with easy-to-use temperature control device that regulates the temperature.

- Teflon bar TM, which greatly improves the durability of the Teflon.

- Foot pedal to activate the machine

- One-year guarantee for the machine parts

- Patented anti-jamming device that detects disabilities and refuses to weld when on Encounters disabilities.

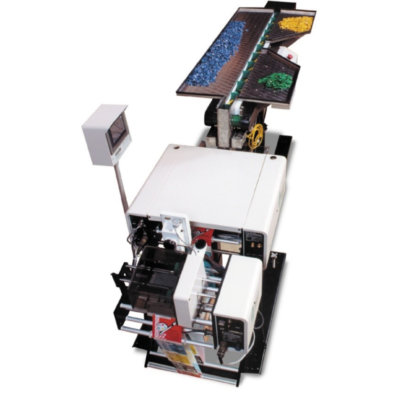

- Universally adjustable funnel as an accessory.

- A sharp jet of air that opens the bag of filtered air.

- Adjustable support board for heavier products as an accessory.

- Easy threading of the bags. Pull the bags off the roll and through the tensioners without them need to thread other roles