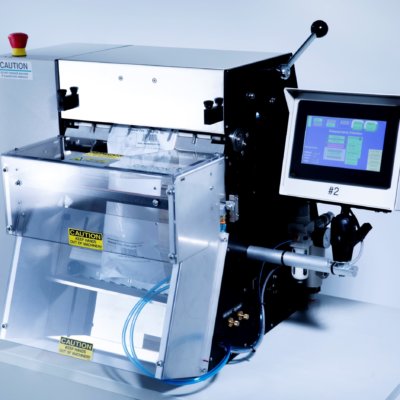

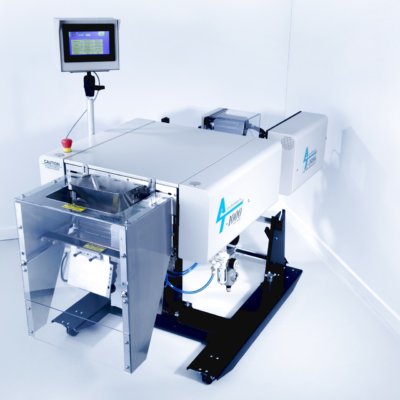

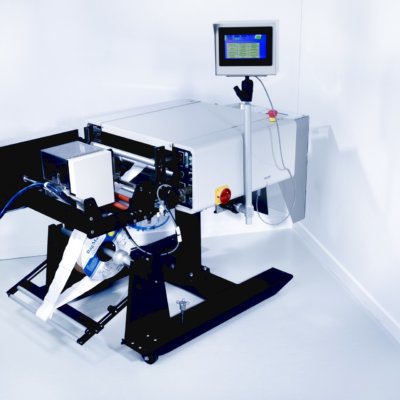

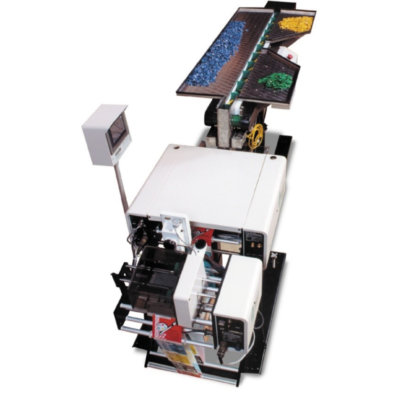

The Ultrawaage US-9000 is the ideal input accessory for pouch packaging with the industrial machines T-1000 and T-1000M. It is both a net scale and a counting unit that can be connected as a module to the bag packaging machine and then controlled from the machine’s touchscreen and works inline. It is particularly suitable for small and / or difficult to separate filler parts. If you are interested in counting the filler parts, hooked parts will be separated and only the really isolated parts will be counted, so that the exact number comes in the bag. However, if you know the total weight of the number of pieces specified as the target, the exact number of pieces in a bag can also be calculated by weighing any connected filler parts, with a tolerance of 0.45 g per bag. And then loading the filler parts into the bag is much faster than any other filler method. Depending on the parts, up to 100 bags per minute can be filled, printed and sealed. Even for different kits and for automatic filling, the US-9000 is a fantastic input aid.

Specifications

Description: US-9000 vibratory conveyor / counting scale

Weight: 220 kg (485 lbs)

Dimensions (floor): 137 cm x 122 cm x 137 cm

(54 “x 48” x 54 “)

Loading height: adjustable from 140 cm to 183 cm

(55 “to 72”)

Loading container for the scales: 11 cm x 25 cm x 10 cm

(4.5 “x 10” x 4 “height) *

Vibratory conveyor: 61 cm ø stainless steel, possibly with

protective coating

Loading direction of the

Vibratory conveyor: counterclockwise

Loading cell: 10 kg

Accuracy: up to 0.45 g

Electricity: 110 / 220V, 60/50 Hz

Air pressure: 2.75 bar

Balance controller, stand, loading container, discharge hopper, manual, one-year parts guarantee.

* The loading container can also be supplied larger to match the size and volume of the filler parts.

Standard dowry:

- Display of exceeding / falling below the target weight.

- Clear for integration with the T-1000 industrial machine for packaging.

- The vibrating base plate with the level measuring arm / switch is standard.

- The weight is updated and displayed ten times per second.

- The parts slide in a steady flow from one

- Loading containers and lessen interference in one Funnel would occur.

- Overweight programming to the system too stop when the limits of the programmed weight are exceeded.

- 61 cm ø (24 “ø) loading conveyor with sliding exit stainless steel. The sides of the output can be adjusted to regulate the output volume become.

- Variable sampling, automatic zeroing, calibration with the keyboard as standard.

- Count display up to 50,000 pieces or weight display in lbs, kg or g.