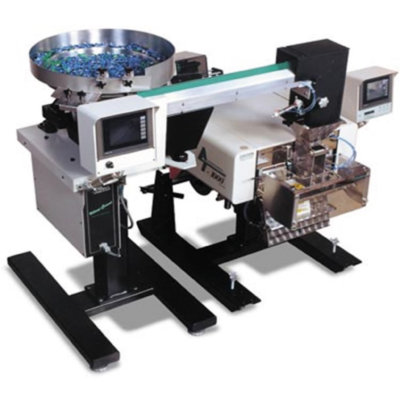

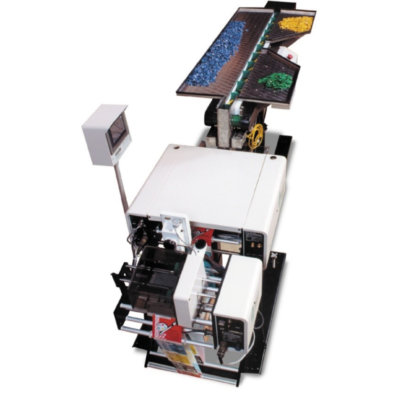

Count small parts precisely and efficiently with a professional automatic small parts counting machine from Bagmatic

Our operator friendly counting machine for small parts makes counting and packaging simple operations possible with unmatched precision. This counting system is specifically designed to be used for bulk counting of small objects with increased output and accuracy levels that eliminate human error. Whether you’re working in manufacturing, warehousing or laboratory settings, this counting technology provides a solution for a wide range of applications. With its advanced automated features and simple operation interface, it’s never been far more flexible to streamline your processes. Contact us today to say goodbye to the frustrating thing of manual counting and hello to Bagmatic’s high-speed counting expertise.

The advantages of a small parts counting machine for your company

The automatic counting system can be an advantageous investment for your operation. These machines are designed as part of a comprehensive approach to eliminate manual counting, which is often the most frustrating thing in production. With technical specifications that ensure accurate counts, you can process many different types of components efficiently. These machines are completely flexible, ideal for counting repeating items like nuts, bolts, or even open-shaped items, making them an asset across industries. This investment will not only streamline operations but also result increase accuracy and productivity, making it ideal for small to medium-sized businesses looking to optimize their processes.

How a small parts counting machine can increase productivity

Our counting applications are an invaluable asset for businesses handling large volumes of components. Sitting at the top of automated bagging machines, these high speed counting solutions automate tedious tasks, significantly improving efficiency. They can process thousands of components with speed the accuracy that human counting cannot match, allowing employees to focus on more complex tasks. The easily retrieved data from each counting cycle helps maintain quality control. As a machine as part of your automation strategy, it delivers consistently reliable results that positively impact your bottom line.

How a small parts counting machine from Bagmatic can help save costs

For manufacturing professionals seeking efficiency, our counting technology offers an economical solution. By implementing our innovative small parts counter, you can reduce labor costs while maintaining exceptional accuracy. You’ll significantly decrease inventory management risks, ultimately improving profitability. One should maintain focus on the benefits of automation – our counting machines deliver fast, precise results that ensure efficient workflow. It’s an investment that consistently delivers value, both financially and operationally.

Small parts counting machines – indispensable for quality control in production

These advanced counting solutions are essential for any production line, consistently delivering reliable results that optimize both time and cost efficiency. They are particularly critical for quality control processes, ensuring precise component counts in each product batch. Production facilities can quickly process the smallest items with extraordinary precision using this technology. This approach minimizes defects, enhances product quality, and improves overall profitability. In today’s demanding manufacturing environment, these counting solutions prove indispensable for achieving maximum efficiency and maintaining rigorous quality standards.