Our highly efficient multihead weighers and combination scales enable you to significantly increase the throughput of your production. These advanced weighing systems, including our multi head weigher machine, are characterized by their ability to perform multiple weighing processes simultaneously. This significantly increases processing speed without compromising on accuracy.

The multi head weighing machine automatically optimizes the combination of individual weighing results to precisely achieve the desired target weight. This reduces overfilling and minimizes product losses. At the same time, the combo scale ensures consistently high product quality thanks to uniform filling quantities.

Increase your throughput with our highly efficient multihead weighers and combination scales

Our weighing systems, such as the multi weigher, can be used flexibly and can be seamlessly integrated into existing production lines. They are suitable for a wide range of products, from food to industrial goods. Thanks to their robust design, these multihead machines can also reliably cope with demanding production environments.

The intuitive user interface of our multihead weigher machine makes it easy to set up and monitor weighing processes. This minimizes downtime during product changeovers and contributes to increasing the overall efficiency of your system. Contact us to find out more about the performance of our multi head scales.

Multihead weighers are your investment in long-term reliability

By choosing our multihead weighers, you are investing in long-term reliability and sustainable efficiency. These robust weighing systems, including our automatic multihead weigher, are designed for continuous operation and prove themselves even under the most demanding production conditions. Their solid construction ensures a long service life with consistently high performance.

Our multi head combination weigher impresses with its ease of maintenance. Regular maintenance work can be carried out quickly and easily, minimizing downtime. The high-quality materials and components used contribute to durability and reduce wear to a minimum.

Another advantage of our multihead weighers is that they are future-proof. Thanks to their modular design, they can be upgraded or adapted to changing requirements as required. This protects your investment and allows you to keep pace with technological developments.

We offer comprehensive support and training to ensure optimal use and maintenance of your multihead combination weigher. This maximizes the service life and efficiency of your weighing system. Find out more about the benefits of our reliable multihead weighers for your long-term business success.

Improve your production processes with multihead weighers

Our multihead weighers offer the potential to fundamentally optimize your production processes. Thanks to their ability to combine different components precisely and quickly, they simplify complex mixing processes considerably. This streamlines your production lines and reduces manual intervention.

The advanced control technology of our multi head weighing machine enables seamless integration into your existing production systems. This allows processes to be automated and coordinated, leading to a reduction in errors and an increase in overall efficiency.

Another advantage of our multihead weighers is their flexibility. You can easily switch between different products or recipes without having to put up with long changeover times. This increases the agility of your production and enables you to react more quickly to market requirements.

By dosing precisely and avoiding overfilling, our multi head combination weigher helps to reduce product losses. This not only optimizes your use of resources, but also increases the profitability of your production. Let's explore together how our multihead weighers can improve your specific production processes.

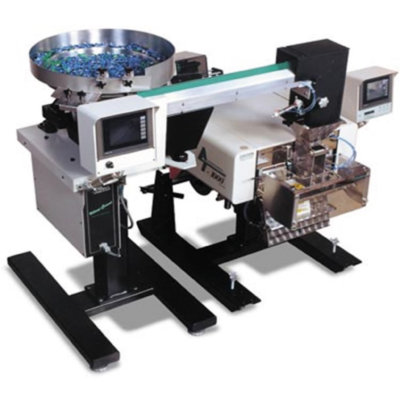

The perfect solution for your industry - combination scales from BagMatic

Our combination scales prove to be the ideal solution for a wide range of industries. Whether in the food industry, the chemical industry or in the consumer goods sector - this versatile weighing system adapts perfectly to the respective requirements.

In food processing, our multihead weigher machine shines with its ability to handle sensitive products gently. At the same time, it guarantees the highest hygienic standards. For the chemical industry, we offer specially equipped models that process even aggressive substances precisely and safely.

In the area of consumer goods production, our multi weigher impresses with its flexibility. It effortlessly handles different product sizes and shapes and enables fast product changeovers. This is particularly valuable in industries with frequently changing product lines.

Our engineers work closely with you to optimize the combination scale to your industry-specific needs. We take into account factors such as product characteristics, environmental conditions and production volumes. Discover how our tailor-made solutions can meet your industry requirements.

Customized multihead weighers for your specific requirements

We understand that every production process is unique. That's why we offer customized multihead weighers that are tailored to your specific requirements. Our experienced team will analyze your production environment and develop a solution that best suits your needs.

The customization options of our automatic multihead weigher are manifold. We can vary the number and size of the weighing heads to handle different product sizes and throughput volumes. Special coatings or materials are available to safely process even aggressive or sticky substances.

We pay particular attention to integration into your existing infrastructure. Our multihead weighers can be seamlessly connected to upstream and downstream processes. The control software can be adapted to your specific requirements to ensure optimum coordination with your production processes.

We support you from the design to the commissioning of your customized multihead weigher machine. Even after installation, we are at your side with comprehensive service. Let us work together to develop the perfect weighing solution for your individual requirements.