Increase Production Efficiency With Our Automatic Premade Pouch Packing Machine

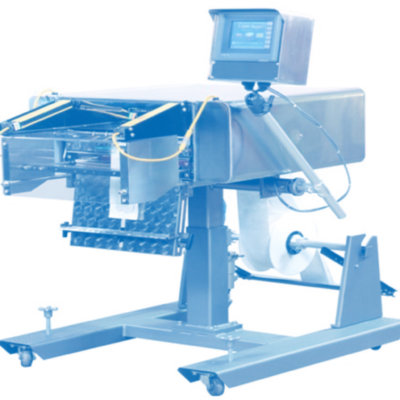

Manufacturing efficiency depends on seamless integration of advanced packaging solutions. Our pre made pouch machine delivers consistent output while reducing manual labor requirements. The rotary premade pouch packing machine processes up to 80 pouches per minute, adapting to various product types and package sizes. Production managers particularly value our premade bag packing machine’s quick-change tooling system, allowing rapid transitions between different pouch formats.

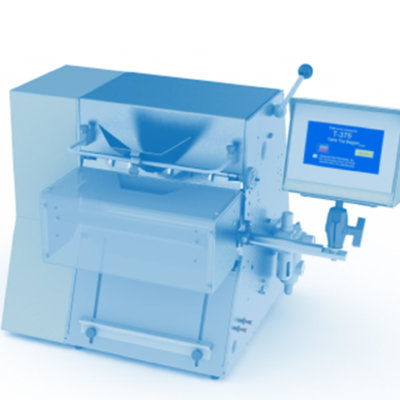

Advanced sensor technology in our premade bag filling and sealing machine monitors fill levels and seal integrity throughout operation. This proactive quality control significantly reduces waste and ensures product consistency. Our premade pouch packaging machine’s intuitive interface enables operators to adjust parameters in real-time, maintaining optimal performance across production runs. Comprehensive diagnostics provide immediate feedback, minimizing potential downtime.

The premade pouch fill and seal machine features a modular design that accommodates future upgrades and modifications as production needs evolve. Integration with existing production lines occurs smoothly through standardized interfaces and protocols. Maintenance requirements remain minimal, with easily accessible components and clear service indicators. Regular operation requires minimal specialized training, allowing facilities to maintain high productivity levels with existing staff.

Why Your Business Needs a Premade Pouch Packing Machine Today

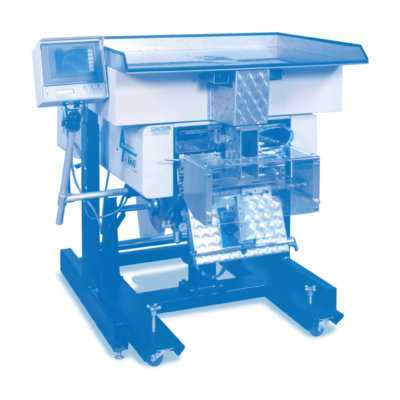

Production volumes continue growing across industries, making manual packaging methods increasingly impractical. The automatic premade pouch packing machine addresses this challenge through automated filling, sealing, and coding processes. Our premade bag packing machine’s precision control ensures consistent product quality while reducing labor costs by up to 60%. Product loss decreases significantly through exact dosing mechanisms and reliable seal verification.

Small and medium enterprises benefit from our premade pouch fill and seal machine through rapid return on investment and reduced operating costs. The rotary premade pouch packing machine’s compact footprint optimizes floor space usage while maintaining high output levels. Automated cleaning cycles minimize maintenance downtime between production runs. Energy-efficient components reduce utility costs while maintaining optimal performance.

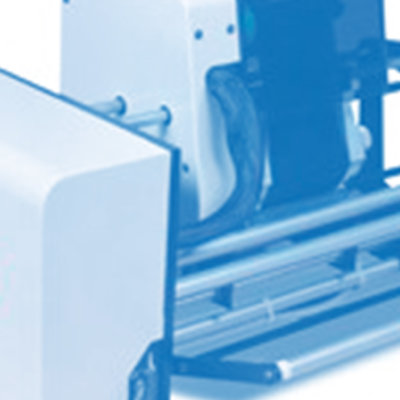

Quality assurance features of our pre made pouch machine safeguard product integrity throughout the packaging process. The premade bag filling and sealing machine’s advanced technology creates reliable, tamper-evident closures that protect contents and extend shelf life. Built-in logging capabilities support compliance requirements and enable process optimization. Production data analysis helps identify opportunities for further efficiency improvements.

Scale Your Business Successfully With Automatic Premade Pouch Packing Machine Systems

Growth demands flexible packaging solutions that adapt to changing market requirements. Our premade pouch packaging machine systems offer scalable automation that grows with your business. Multiple product lines integrate smoothly through standardized controls and interfaces. The system’s modular architecture enables capacity expansion without disrupting existing operations.

Custom configurations of our premade pouch fill and seal machine accommodate specific product requirements and packaging formats. The automatic premade pouch packing machine handles both liquid and solid products with equal accuracy. Automated cleaning and sanitization features maintain hygiene standards while minimizing downtime. Remote monitoring capabilities enable proactive maintenance scheduling and performance optimization.

Production planning becomes more predictable with our premade bag packing machine through consistent cycle times and reliable operation. The rotary premade pouch packing machine’s advanced controls maintain precise fill weights and seal quality across extended production runs. Integrated quality checks ensure package integrity before products leave the production line. Real-time performance metrics support continuous improvement initiatives.

Expert Support for Your Premade Pouch Packaging Machine Investment

Technical expertise remains available throughout the lifecycle of your pre made pouch machine. Our engineering team provides comprehensive installation planning and site preparation guidance. Factory-trained technicians ensure proper configuration and optimization of your premade bag filling and sealing machine for specific production requirements. Ongoing support includes regular system health checks and performance optimization recommendations.

Training programs equip operators with essential skills for daily operation and routine maintenance of the premade pouch packaging machine. Documentation covers standard procedures, troubleshooting guides, and maintenance schedules in detail. Remote diagnostics capabilities enable rapid response to technical queries and minimize potential downtime. Software updates introduce new features and maintain system security without disrupting production schedules.

Application specialists assist with new product implementations and packaging format changes for your automatic premade pouch packing machine. Our spare parts inventory ensures quick delivery of critical components when needed. Preventive maintenance programs help maintain optimal performance and extend equipment life. Regular calibration services verify measurement accuracy and maintain product consistency.

Boost Production Numbers With Our Premade Pouch Packing Machine Technology

Production optimization starts with reliable, efficient packaging equipment. The premade pouch fill and seal machine incorporates advanced servo controls for precise operation. Automatic format adjustments reduce changeover times between different package sizes and styles. The premade bag packing machine maintains consistent quality at rates up to 80 pouches per minute.

Integrated weight control systems in our rotary premade pouch packing machine ensure accurate filling across various product types. Smart sensors monitor critical parameters throughout the packaging process. The pre made pouch machine’s robust construction withstands demanding production environments while maintaining precision. Automated clean-in-place systems reduce maintenance requirements and ensure hygienic operation.

Production managers appreciate the premade bag filling and sealing machine’s comprehensive data collection capabilities. Real-time monitoring enables immediate response to process variations. The user interface provides clear visibility of machine status and production metrics. Advanced diagnostics help identify potential issues before they impact production. Automated report generation supports quality documentation and process improvement initiatives.