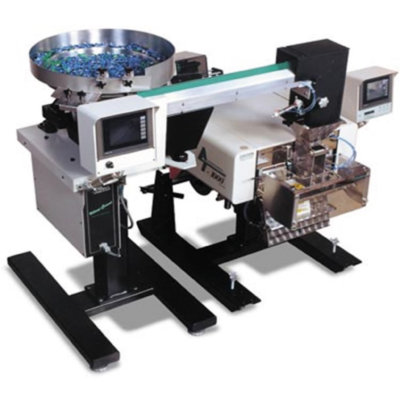

BAGMATIC small parts counting machine for various parts

The Bagmatic small parts counting machine is a universal automatic parts counter for small and irregularly shaped parts, such as:- Finest plant seeds like tomato, patato, carrots etc.

- Vegetable seeds

- Canabis

- Cereals, Corn, Rice, Granola

- Insects, Pupae

- Pharmaceuticals, pills, casules

- Gems, diamonds and precious stones

- Small mechanical parts, spacers, bearings,

- Implants

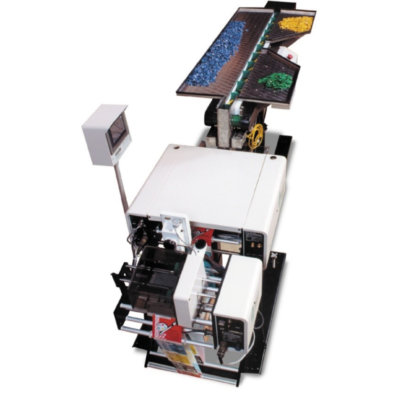

US-5000 semi-automatic weighing / counting system

US-5500 Ultra scale with PTL (Pick-to-Light)

US-9000 Ultra-scale net scale & counting unit

T-1000H horizontal industrial machine for packaging

State-of-the-Art Order Picking Machines for Efficient Operations in Your Company

Our company manufactures warehouse order picker machines incorporating the latest technology. These stock picker machines improve material flow through precise control systems and significantly reduce order processing times. The functionality of our order picking machines stems from decades of development work and practical experience in warehouse management. Through systematic technological advancement, we achieve high process stability in order fulfillment.

Documentation of each work step occurs automatically during the picking process. The integrated control system records all stock movements and reconciles them with order details. The continuous monitoring through our picker machine warehouse systems ensures error-free order compilation. Through comprehensive tracking, warehouse staff maintain overview of available inventory.

Future-Proof Automation of Your Warehouse Processes with an Industrial Order Picking Machine

The control system of a modern warehouse picker machine processes orders independently according to defined parameters. The software plans the sequence of picking operations considering delivery deadlines and available resources. Path optimization minimizes unproductive time during order processing. The interplay of mechanical and electronic components ensures economical operation.

The design of our order picking machines enables adaptations to changing requirements. The base system can be expanded with additional modules and adjusted to increasing throughput volumes. Interfaces to existing warehouse management systems follow current standards. The employed technology aligns with the needs of growing enterprises.

Secure Your Competitive Edge with Flexible Stock Picker Machines

Operating a warehouse order picker machine improves processes throughout the logistics chain. The system plans picking routes proactively and reduces waiting times. Even distribution of orders prevents overload of individual areas. Flexible adaptation to fluctuating order volumes stabilizes delivery capability.

Technical support in the picking process creates measurable advantages. The order picking machine works with consistent precision and enables on-time delivery. The consistently high quality of order compilation strengthens customer loyalty. Punctual and accurate deliveries contribute to client satisfaction.

Maximum Efficiency Through Perfectly Tailored Warehouse Picker Machines

The technical equipment of the picker machine warehouse systems aligns with the characteristics of the goods to be processed. Analysis of operational processes forms the basis for system configuration. The mechanical and electronic assemblies correspond to specific product requirements. Installation takes place considering spatial conditions.

The coordination of system components ensures trouble-free operation. The warehouse order picker machine communicates seamlessly with adjacent processes. The user interface enables quick staff training. System performance is evident from the first day of operation.

The Benefits of an Order Picking Machine for Your Company

Acquiring a stock picker machine leads to verifiable savings. Automation reduces personnel requirements in order processing. Electronic recording simplifies the management of stock movements. Process optimization lowers operating costs.

Process reliability increases significantly through the use of warehouse picker machines. The system prevents errors during order compilation and ensures delivery quality. Continuous documentation supports inventory management. Time savings create space for customer care.

Benefit from Years of Experience in Developing Order Picking Machines

Knowledge from numerous projects flows into the continued development of our picking machines. The engineers understand the requirements of daily operations. Exchange with users shapes the technical design of the systems. The quality of the equipment is based on practical experience.

Direct communication with our customers determines the collaboration. We support you from planning through to ongoing operation of your warehouse order picker machine. Our service technicians are available for maintenance and support. Schedule an appointment for a detailed consultation.