What does a linear feeder do?

Linear feeders are systems in the field of feeding technology that are mainly used for the horizontal transport of workpieces of different sizes. As a unit in the automation series, linear feeders operate alongside other components of feeding technology such as spiral conveyors and vertical wall conveyors. In contrast to other systems of conveyor technology in this area, such as conveyor belts, linear feeders can also be classified as so-called vibratory conveyors.

Basically, a linear feeder is similar to a type of vibratory device in which workpieces or bulk materials of different sizes are transported from a storage container via a linear feeder track to their destination with the help of vibrations such as vibration increase. Conveyor elements generally resemble conveyor pipes or troughs and can be sized to fit the workpieces being conveyed. The high precision engineering behind these systems ensures consistent and reliable operation, even in demanding industrial environments.

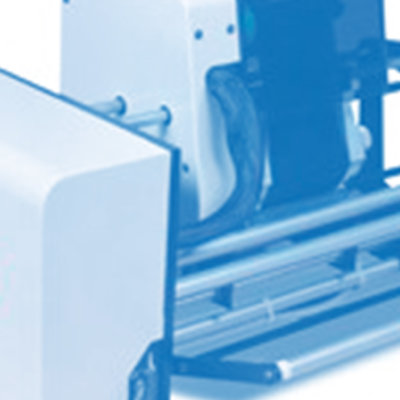

The conveying pipe or channel is always horizontal. This means that linear feeders can only provide transport on one level. To overcome smaller vertical alignment distances, the conveyor element may be tilted upwards or downwards by up to 10 degrees if necessary. To transport parts, the linear feeder vibratory unit or the conveyor trough moves upwards in a small jerky movement at the same time as the transport direction. During this movement, the bulk material is in a way carried along and lifted together with the chute. When the chute lowers and returns, the inertia causes the bulk material to remain stationary or to fall down. Each vibration pushes it forward a little. The transport speed of the linear feeder depends on the vibration frequency and can be adjusted individually to ensure consistent flow.

Where are linear feeders used?

Linear vibratory feeders are used when workpieces need to be reliably transported from A to B. Individual adjustment options allow the conveyor speed to be individually adapted based on the vibration frequency. At the same time, linear vibratory feeders can be adapted to workpieces of different sizes. Everything from pebble-sized bulk material to dusty grain can be conveyed on linear feeders. The installation of these systems requires careful planning to extend their operational lifespan and ensure maximum efficiency in your production line.

Overall, the conveyor system is considered very durable, robust and low-maintenance. Moreover, jams and blockages rarely occur. This is because these can usually be cleared quickly in a natural way by the movement of the swing. Conveying on linear feeders is particularly gentle and smooth, even over long distances. Linear vibratory feeders may also act as buffer or accumulation sections in complex plants to keep the production chain running. Their availability in various series and configurations makes them suitable for a wide range of industrial applications.

The drive unit in these systems is engineered to provide maximum efficiency while maintaining high reliability. In some advanced automation series, the escapement mechanisms can be completely different from traditional designs, offering greater precision for specialized applications. Inline feeders may be integrated into existing production lines through careful order planning and strategic placement. This integration allows manufacturers to create a seamless flow of parts from one process to the next, eliminating unnecessary handling and potential damage to sensitive components.

Linear conveyors – optimise your processes

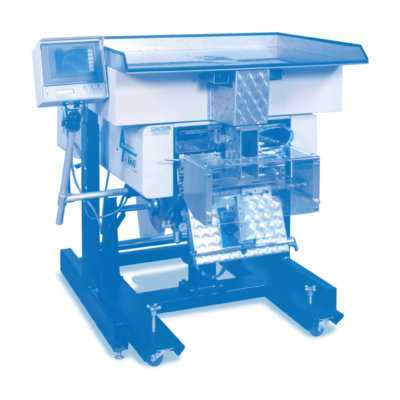

Packaging is routinely used in a wide range of industries around the world to protect goods and facilitate transport. The pouch packaging machine is an important process factor as it facilitates the handling of individual products and as a packaging machine manufacturer we specialise in developing individual solutions for your products. In the medium to long term, the right pouch and film solutions can reduce costs and increase productivity and efficiency. The engineering behind our systems focuses on consistent performance and reliable operation throughout extended production runs.

We offer a wide range of industrial and benchtop machines for different applications, which you can choose depending on your industry and application. To order the right unit from our series, you may want to consult our engineering team who can help extend the functionality to match your specific needs. Our comprehensive list of available options ensures that you can find the perfect solution for your specific requirements, whether you need high-speed operation or specialized handling capabilities.

Packaging and related machines operate semi-automatically and fully automatically, so you can choose a packaging machine to suit your individual needs and requirements. Packaging is always part of it and, depending on the printing, colour or shape of the individual bags, films or packaging, can also serve as an actual advertising medium. A fully automatic inline printer or QR and barcode for bag packaging ensure a highly individual presentation of your products. The storage options available with our systems allow for efficient management of packaging materials and finished products.

Linear vibrating feeder – Bag packaging machines

Especially in production, machines are of utmost importance and must work reliably. Breakdowns and problems can take up time and disrupt the entire process. Our packaging options allow you to find reliable and complete solutions for your industry. Our industrial machines are typically suitable for all products that need to be neatly packaged in film or pouch packaging. The drive mechanisms in our equipment are designed for continuous operation with minimal maintenance requirements, ensuring your production line remains operational with maximum uptime.

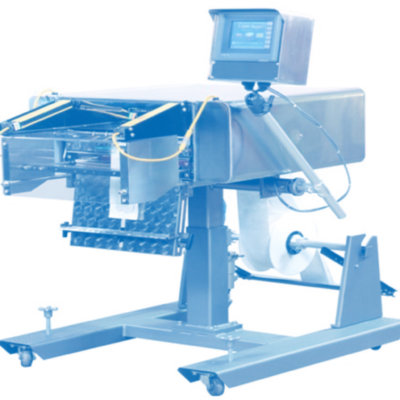

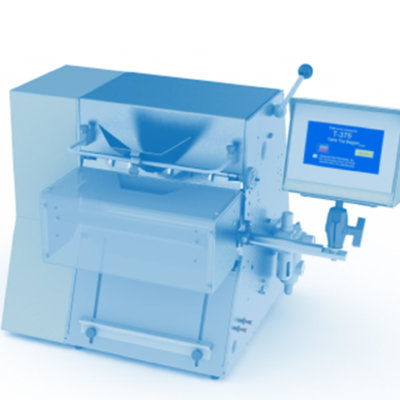

Our system solutions also include customisable input accessories or printers. So you can reliably print and fill bags semi-automatically or fully automatically with our complete solution. Our T-1000 model is our best-selling packaging machine and is perfectly tailored to your personal needs, allowing you to significantly increase your productivity. The automation series we provide can be completely different from one installation to another, as we customize each solution to match the specific requirements of your production environment.

Our industrial machines for packaging requirements are very fast and flexible, the speed depends mainly on the size, shape and number of individual parts. With a maximum capacity of up to 100 bags per minute, nothing stands in the way of efficient production. The automatic machine is designed to transport parts directly from your production line to packaging, creating a seamless workflow that reduces handling and increases throughput. By maintaining a high level of consistency throughout the process, our systems help ensure product quality while maximizing production efficiency.

Industry-specific solutions

Industry-specific packaging solutions must define critical parameters such as size, speed and hygiene. Industrial form fill and seal machines are typically used vertically or horizontally in the machine building, tooling, food and pharmaceutical industries. The automatic machine is to be connected to other equipment such as punch presses and injection moulding machines, for example, to automatically transport parts after completion for packaging. Our engineering team can provide customized track designs that may extend beyond standard configurations to meet your specific production needs.

The cleanliness required for use in the medical sector is ensured by the quality of the film used and the stainless steel construction of the horizontal and vertical continuous packaging machines. In addition, the air used for the opening mechanism is individually filtered and attention is paid to special temperature settings during the process. The installation of these systems in controlled environments may also include specialized enclosures to maintain the highest level of cleanliness throughout the packaging process.

Table-top machines are often used not only for small parts, but also for books, food, electronic parts and jewellery. Any horizontal or vertical form, fill and seal packaging machine can be equipped with valuable additional equipment to optimise other processes. We maintain a comprehensive list of available options that may help you determine which drive system and automation features best suit your production needs. Our series of compact units provides consistent performance while requiring minimal floor space, making them ideal for facilities where space is at a premium or for companies looking to expand their production capacity without expanding their physical footprint.