Automation solutions – We are at your side with advice and support

Automation solutions in mechanical engineering consist of the automatic monitoring, control and regulation of technical processes without human intervention. The more complex the tasks to be performed independently, the higher the degree of automation. Whether in manufacturing, assembly or handling, the automation of these processes is essential in the industry in order to survive in the growing competition. We are an automation solutions company and help our customers save time and money by automating the selection of the right hardware and software. There are countless possibilities to automate machines and plants. With us you have found the right partner to select the right solution for your application. Our experts are trained in all common systems and robot controllers and will assist you in selecting and developing the right technology.

We have the right automation solutions for you

Every industry has unique requirements. The technical complexity is constantly increasing. Together with you, we will develop an economical solution for your new plant. Thanks to our closely coordinated design, electrical engineering and automation know-how, you receive a precisely coordinated overall solution from a single source. Our multidisciplinary team uses the knowledge from mechanical design to optimally match the electronics to the mechanical design. Perform project analysis, planning and software development to manage the customer. We handle installation, commissioning, service and maintenance. Our automation solutions are precisely tailored to each individual machine so that everything from sensors to interfaces work together perfectly. Advice on which technology solution to use for maximum ease of use. We respond flexibly to adaptation requests following production changes.

Automation systems technology – Packaging Robots

In packaging and filling processes, speed is a very important factor for long-term efficiency. As long as manual processes are involved in the packaging line, there are clear limits to what can be done. In addition to limiting the speed of expert work, manual work naturally increases the potential for errors. If you want to take your packaging process to the next level, we recommend using a packaging robot. State-of-the-art robotics and vision systems combine precise process execution with uniquely fluid, fast processes. Thanks to visual quality control, you don’t have to worry about unnoticed errors. In this way, our automated robots and machines impress not only in terms of documentation, but also in terms of efficiency.

Articulated arm robots are used particularly frequently in modern packaging and filling systems. These are particularly flexible packaging robots that are suitable for general applications. High-performance industrial robots are particularly popular in the automotive industry. The versatility of jointed-arm robots stems from the fact that they have serial kinematics, i.e., they have multiple jointed arms and rotary axes that enable movement in three dimensions. When using jointed-arm robots for manufacturing or filling, you have a choice between vertical jointed-arm robots and horizontal jointed-arm robots. Whatever type of packaging robot or machine you choose, it can be easily and fully integrated into your existing system.

Automation solutions – Convince yourself of our jointed-arm robots

Jointed-arm robots are used particularly frequently as pick-and-place robots. Versatile jointed-arm robots can be equipped with various tools that serve different purposes in the packaging and filling process, so that different packaging materials can be easily handled by packaging robots. Additional linear axes can be equipped with vertical articulated arm robots or horizontal articulated arm robots for further applications. With the help of rails, pick-and-place robots can easily bridge distances between several workstations and perform different tasks one after the other. Alternatively, rails can be mounted on walls or ceilings, making packaging robots particularly mobile.

The capabilities of our packaging robots vary depending on the model and equipment. Therefore, it is also suitable for different processes. Feel free to contact us for advice on suitable equipment. Vertical jointed-arm robots and horizontal jointed-arm robots have in common that they are capable of technically complex manipulations and can perform several work steps without interruption. In particular, the 6-arm pick-and-place robot offers a high degree of automation in a single device. The disadvantage of the limited reach in contrast to gantry robots can be compensated by the linear axes mentioned above. Even if you need a trained expert to program this packaging robot, using a highly automated robot can save many resources.

Individual automation solutions for your company

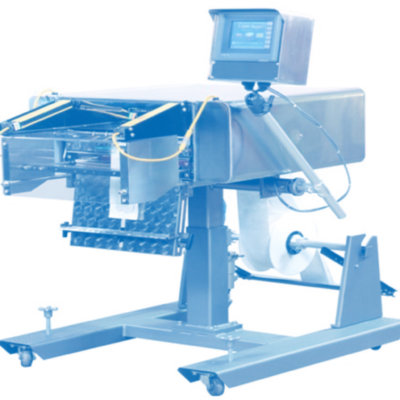

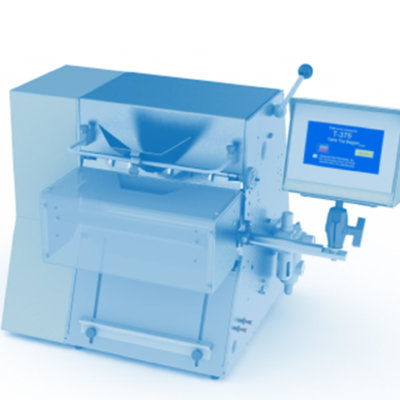

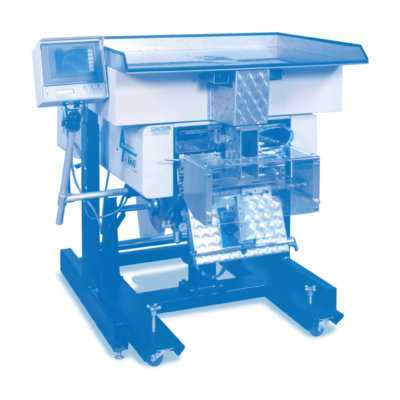

It is important to be able to add packaging robots to existing lines in order to gradually switch to automated lines. That is why we offer various automation control solutions for combining automated robots with other packaging equipment. For example, a collaborative robot (Cobot) can be combined with our vision system and another Bagmatic packaging machine, including a Zebra printer. But it can also be combined with standard robots. Whether you choose a Cobot or a standard packaging robot, this effective automation systems technology can be easily expanded with flexible separation or parts feeding systems. The latter works without cooperating robots in conjunction with packaging machines and Zebra printers. You are welcome to contact us. We will be happy to advise you on suitable expansion options for your Bagmatic automation solutions.