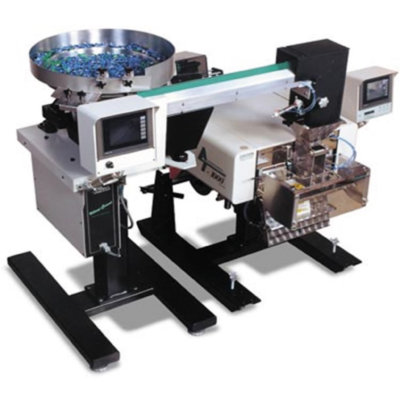

BAGMATIC small parts counting machine for various parts

The Bagmatic small parts counting machine is a universal automatic parts counter for small and irregularly shaped parts, such as:- Finest plant seeds like tomato, patato, carrots etc.

- Vegetable seeds

- Canabis

- Cereals, Corn, Rice, Granola

- Insects, Pupae

- Pharmaceuticals, pills, casules

- Gems, diamonds and precious stones

- Small mechanical parts, spacers, bearings,

- Implants

US-5000 semi-automatic weighing / counting system

US-5500 Ultra scale with PTL (Pick-to-Light)

US-9000 Ultra-scale net scale & counting unit

T-1000H horizontal industrial machine for packaging

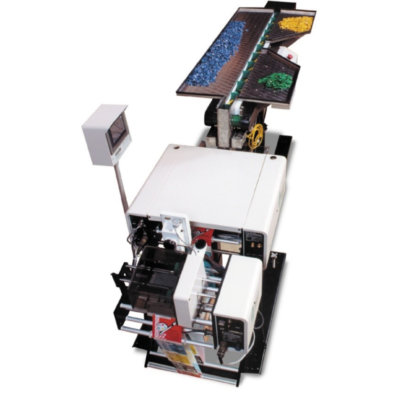

Customized Pick and Place Machines for Efficient Production Processes

We develop pick and place machines precisely tailored to your company’s needs. Our pick and place systems stand out through precise processing and reliable functionality. Direct collaboration with the manufacturer enables flexible adaptations to your production requirements. An experienced development team supports you from planning to commissioning.

The efficiency of modern pick & place machines is particularly evident in processing various materials and formats. Through advanced control technology, our pick and place automation systems ensure consistently high quality with maximum productivity. Integration into existing production lines occurs smoothly and systematically.

Our customers especially value the durability and maintenance-friendly design of our pick and place robots. The well-thought-out design enables quick format changes and minimizes downtime. Contact us for detailed consultation regarding your specific requirements.

High-Quality PnP Machines for Future-Oriented Companies

The demands on modern pick and place systems continue to grow. We meet this development with technically sophisticated solutions. Our automatic pick and place machines combine precision with high processing speed. The robust construction guarantees long service life with consistently high performance.

A key advantage of our pick and place feeders lies in their flexible adaptability. The control systems enable quick changeover to different product formats. Through continuous development, our systems remain technically state-of-the-art.

Quality assurance plays a central role in manufacturing. Each pick and place machine undergoes extensive testing under real conditions. Schedule an appointment at our facility and see the processing quality for yourself.

Your Requirements Define Our Pick and Place Solutions

Every company has specific production processes. Our pick and place automation systems adapt to these individual requirements. The modular design enables various configurations for optimal results. A personal contact person accompanies you throughout the entire project phase.

The development of a manual pick and place machine begins with a thorough analysis of your processes. We consider factors such as throughput performance, material variety, and automation level. The result is pick & place machines that perfectly fit your production environment.

Flexibility also means being able to react to changing market requirements. Our pick and place systems can be subsequently expanded and adapted. Utilize our experience to optimize your production processes.

Optimize Your Packaging Processes with State-of-the-Art Pick and Place Technology

Efficient packaging processes require sophisticated automation solutions. Our pick and place robots process different materials with highest precision. The integrated control systems ensure consistently high quality. Modern sensor and control technology enables reliable process monitoring.

The use of a PnP machine notably increases productivity. Through short setup times and simple operation, you achieve maximum flexibility. The systems operate energy-efficiently and conserve resources. Ask about our reference projects in your industry.

Pick and Place Systems That Make Your Company Competitive

Economic success is based on efficient production processes. Our pick and place automation solutions contribute significantly to process optimization. The combination of speed and precision secures your market advantage. We place special emphasis on future-proof technologies.

Investment in a modern pick and place feeder quickly pays off. Through increased productivity and reduced error rates, you noticeably lower unit costs. Our financing models enable optimal planning of your investment.

Benefit from our years of experience as a manufacturer. We support you in selecting the right pick and place machines for your requirements. Schedule a consultation now for detailed information about our systems.