Pouch packaging has become a ubiquitous presence in the modern marketplace, transcending a myriad of industries due to its remarkable versatility, efficiency, and increasing focus on sustainability. This form of packaging, characterized by its flexible, non-rigid structure, can be customized to fit a wide range of products, from liquids and powders to solid goods. Its rise to prominence is not just a testament to its practicality in protecting and preserving products, but also to its adaptability in meeting the evolving demands of consumers and businesses alike.

The appeal of pouch packaging lies in its multifaceted benefits. It offers significant cost savings in production and transportation, as its lightweight nature reduces freight costs and its compact design maximizes shelf space. From a sustainability perspective, pouches often require less material to produce than traditional rigid packaging, leading to a reduction in resource consumption and waste generation. Furthermore, advancements in pouch materials and designs have enhanced their functionality, allowing for features such as resealability, improved barrier properties, and convenient dispensing mechanisms.

The Evolution of Pouch Packaging

The history of pouch packaging is a fascinating journey that mirrors the advancement of human civilization and technology. From its rudimentary beginnings to the innovative and sustainable options we see today, pouch packaging has evolved significantly over time, adapting to meet the changing needs of society and industry.

Early Beginnings and Material Innovations

Initially, pouch packaging was as simple as using natural materials like leaves or animal skins to transport and store food. These early forms of pouches were functional but limited in durability and protective qualities. However, the industrial revolution brought about a paradigm shift. The introduction of paper and later, plastic materials, revolutionized pouch packaging. Material innovations such as laminates, which combined the strength and durability of plastics with the barrier properties of metals like aluminum, greatly expanded the effectiveness and application areas of pouch packaging. These advancements allowed for the packaging of a wide variety of goods, from perishable food items requiring airtight seals to non-food products needing durable packaging solutions.

Technological Advancements in Pouch Production

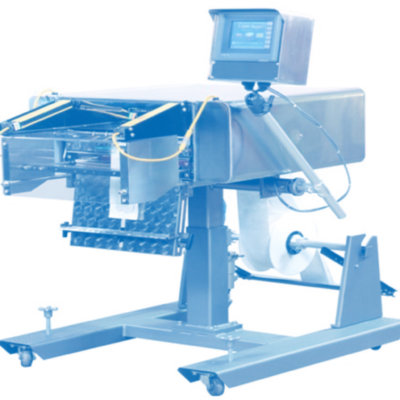

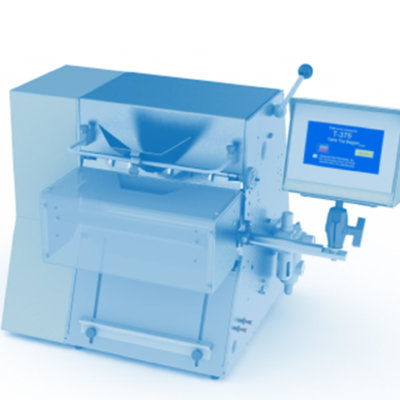

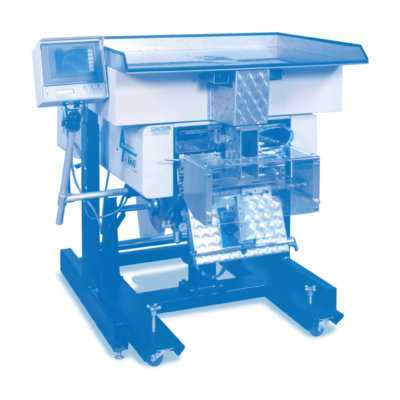

The evolution of pouch packaging is also marked by significant technological advancements that have streamlined production processes. In the early days, pouch making was a largely manual or semi-automated process, which was time-consuming and less efficient. The development of fully automated pouch production lines changed the landscape entirely. Modern machinery now offers high-speed, precision manufacturing of pouches, significantly improving both quality and output while reducing waste. Digital printing technology has further revolutionized pouch production by enabling high-quality, customizable packaging designs without the need for expensive and time-consuming plate-making processes. Additionally, advancements in sealing technologies have improved the integrity and longevity of pouches, ensuring better product protection and extending shelf life.

These material and technological innovations have not only made pouch packaging more effective but have also opened the doors to more sustainable packaging solutions. Today, the focus is on developing materials that are biodegradable or recyclable, and technologies that minimize environmental impact, marking a new chapter in the ongoing evolution of pouch packaging.

Types of Pouch Packaging

Pouch packaging continues to evolve, with various types now available to meet the diverse needs of different industries. Each type offers unique advantages and is designed with specific applications in mind, from preserving the freshness of food and beverages to ensuring the durability of non-perishable goods.

Stand-up Pouches

Stand-up pouches are designed to stand upright on their own, thanks to the gusset at the bottom, which expands when the pouch is filled. This design not only enhances product visibility on shelves but also maximizes space efficiency. The advantages of stand-up pouches include their resealability and the ability to incorporate various features such as zip locks, spouts, or tear notches for convenience. Commonly used in the food and beverage industry for snacks, pet food, and drinks, they are also prevalent in the personal care sector for products like shampoos, lotions, and more. The versatility and consumer-friendly aspect of stand-up pouches make them a popular choice across these industries.

Flat Pouches

Flat pouches, characterized by their simple, flat design, are a cost-effective solution for packaging single-use or smaller products. They take up minimal space and material, making them an environmentally friendly packaging option. These pouches are typically used for products that do not require a standing feature for display, such as samples, spices, or pharmaceuticals. The structure of flat pouches allows for easy storage and distribution, and their straightforward design can be leveraged for impactful product branding and information dissemination.

Spouted Pouches

Spouted pouches come equipped with a spout and cap closure, providing an ideal solution for liquid packaging. These pouches offer the dual benefits of flexible packaging and user-friendly, mess-free dispensing. Perfect for beverages, sauces, soaps, and even automotive fluids, spouted pouches ensure the contents are securely contained yet easily accessible. The design features cater to both convenience and functionality, supporting portion control, reusability, and safe storage, thereby serving a wide range of liquid packaging needs in various sectors.

Retort Pouches

Retort pouches are made from a multilayer combination of plastics and metal foils, creating a strong barrier against contaminants and extending the shelf life of the product. They are designed to withstand the sterilization process known as retorting, where the pouch and its contents are heated to high temperatures to kill off bacteria, making them perfect for ready-to-eat foods, pet foods, and military meals. The construction of retort pouches combines the advantages of canned goods—long shelf life and safety—with the benefits of flexible packaging, including lightweight and reduced storage space. Their use significantly reduces the energy required for transportation and storage, driving their popularity in industries requiring extended shelf life without the need for refrigeration.

Materials Used in Pouch Packaging

The choice of materials in pouch packaging plays a crucial role in determining its suitability for different products, impacting everything from durability and barrier properties to sustainability and recyclability. The industry has seen significant innovation in material development, aiming to balance functionality with environmental responsibility.

Plastic-Based Pouches

Plastics are the most widely used materials in pouch packaging due to their versatility, durability, and cost-effectiveness. Common types include polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET), each offering unique properties that make them suitable for different applications. For example, PET is known for its strength and clarity, making it ideal for the outer layer of pouches, while PE offers flexibility and sealability, often used in the inner layer. Despite their advantages, the widespread use of plastics raises environmental concerns, particularly regarding their disposability and the challenges associated with recycling mixed-material pouches. The industry is responding by exploring more recyclable options and developing infrastructure to better manage plastic waste.

Aluminum and Foil Pouches

Aluminum and foil materials are prized in pouch packaging for their excellent barrier properties against light, oxygen, and moisture, which significantly extend the shelf life of the packaged product. They are commonly used in the food industry, particularly for retort pouches and high-barrier needs. However, recycling aluminum and foil pouches presents challenges due to the need for separation from other materials and the cleaning required to remove product residues. Despite these challenges, the high value of aluminum makes it a more likely candidate for recycling efforts compared to some plastics.

Biodegradable and Compostable Pouches

In response to increasing environmental concerns, the development and adoption of biodegradable and compostable pouch materials have gained momentum. These materials, derived from renewable resources like corn starch, cellulose, and even algae, are designed to break down under specific conditions, reducing their impact on landfill and marine pollution. While these materials mark a significant step towards sustainable packaging, there are challenges to overcome, including the current limitations in industrial composting facilities and the need for clear labeling to avoid confusion among consumers. Despite these hurdles, the interest in biodegradable and compostable pouches continues to grow as industries seek to align their packaging choices with environmental sustainability goals.

The diversity of materials used in pouch packaging reflects the industry’s efforts to meet the demands of various products and priorities, from preserving freshness and extending shelf life to minimizing environmental impacts. As technology advances and consumer awareness increases, the development of new materials and the improvement of recycling and composting infrastructures will continue to shape the future of pouch packaging.

Benefits of Pouch Packaging for Industries

Pouch packaging has significantly influenced the packaging industry, offering a range of benefits that cater to manufacturers, retailers, and consumers alike. These benefits span cost savings, operational efficiencies, customer appeal, and environmental sustainability, making pouch packaging a versatile and attractive option across various sectors.

Enhanced Product Protection

One of the primary benefits of pouch packaging is its superior product protection capabilities. Pouches are designed with layers of materials that offer excellent barrier properties against environmental factors such as moisture, oxygen, light, and contaminants, significantly extending the shelf life of the products they contain. This is particularly advantageous for the food and beverage sector, where preserving product freshness and quality is paramount. Additionally, the flexibility of pouches can provide better resistance to impacts during transportation, reducing the risk of damage and spillage.

Marketing and Branding Opportunities

Pouch packaging offers ample opportunities for marketing and branding, thanks to the versatility in shapes, sizes, and printing technologies. The entire surface area of a pouch can be utilized for high-quality graphics and product information, making it an effective tool for establishing brand identity and conveying key messages directly on the packaging. Customizable designs allow brands to stand out on crowded shelves and create a distinctive look that attracts consumers. Furthermore, innovations like transparent windows or unique shapes can enhance product visibility and appeal, further driving consumer interest and engagement.

Environmental Impact and Sustainability

The environmental impact of packaging is a growing concern among consumers and industries alike. Pouch packaging addresses some of these concerns through its lightweight nature and reduced material usage compared to traditional rigid containers, leading to lower transportation costs and a reduced carbon footprint. Furthermore, ongoing efforts to improve sustainability in pouch packaging include the development of recyclable, biodegradable, and compostable materials. These initiatives aim to reduce waste and facilitate a shift towards more circular economy models. However, challenges remain in terms of recycling infrastructure and market penetration of sustainable materials, but the industry’s focus on innovation indicates a positive trajectory toward minimizing environmental impacts.

The cumulative advantages of pouch packaging underscore its growing adoption across industries. Its ability to offer enhanced product protection, marketing and branding benefits, and potential for reduced environmental impact makes it a compelling choice for businesses looking to optimize their packaging strategies while meeting consumer expectations for convenience and sustainability.

Challenges Facing the Pouch Packaging Industry

While pouch packaging offers numerous benefits, it also faces significant challenges. These include navigating regulatory pressures, addressing recycling complexities, and managing consumer perceptions—all of which are critical for the industry’s sustainable growth.

Recycling and Waste Management Issues

One of the most pressing challenges for the pouch packaging industry is the complexity of recycling pouch materials. Pouches often comprise multiple layers of different materials to achieve desired properties like barrier protection and durability. However, these multi-material designs can make recycling difficult because current recycling facilities are not equipped to separate and process these materials effectively. This results in a significant amount of pouch packaging ending up in landfills or incinerators.

To address these issues, the industry is exploring several initiatives. These include developing mono-material pouches that are easier to recycle, investing in advanced recycling technologies capable of processing complex materials, and participating in extended producer responsibility (EPR) programs to support the recycling infrastructure. Additionally, there is a push towards designing for recyclability from the outset, ensuring that new pouch products are compatible with existing recycling systems.

Adapting to Regulatory Changes

The pouch packaging industry must also adapt to an evolving regulatory landscape focused on material use and waste management. Governments around the world are implementing stricter regulations to tackle plastic pollution and promote a circular economy. These regulations may include bans on certain types of plastics, requirements for increased recycled content in packaging, and mandates for packaging to be recyclable or compostable.

Navigating these regulatory changes requires agility and innovation from the pouch packaging industry. Manufacturers are being prompted to reassess their material choices, invest in research and development for more sustainable packaging solutions, and engage in policy discussions to help shape practical and effective regulations. Compliance with these changing regulations not only helps in mitigating environmental impacts but also aligns companies with growing consumer demand for sustainable packaging options.

Consumer Perceptions

Consumer perceptions pose another challenge for the pouch packaging industry. While many consumers appreciate the convenience and functionality of pouch packaging, there is increasing scrutiny over its environmental impact, particularly concerning single-use plastics. Misinformation and lack of awareness about the recyclability and sustainability benefits of certain pouch packaging solutions can further complicate this issue.

To improve consumer perceptions, the industry needs to focus on education and transparency. This involves clearly communicating the environmental benefits of innovative pouch packaging, such as reduced carbon footprint and material efficiency, and providing clear instructions for disposal and recycling. Engaging consumers through awareness campaigns and labeling initiatives can help bridge the gap between perception and reality, fostering a more informed and positive view of pouch packaging solutions.