Friction feeders – For your individual project

MF friction feeders are high-performance feeders that are used wherever maximum performance and accuracy are required. The friction feeder is designed for continuous use in the packaging industry and has an integrated touch panel for easy operation and recipe management. The modular design of the friction feeder allows the distributor to be adapted to different customer requirements. The easy-to-maintain design allows operators to perform maintenance quickly and cost-effectively, resulting in less production line downtime. The Whizzy friction feeder is an automatic feeding machine for feeding and dispensing flat products that can be placed at a selected point with the highest precision.

Request your friction feeder now:

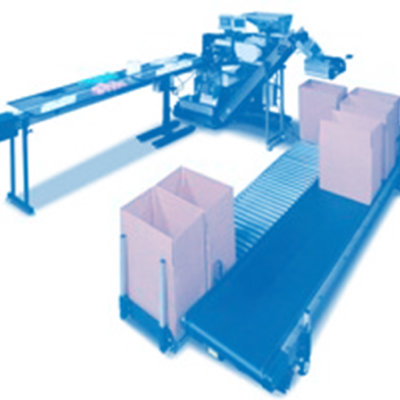

From folding carton assembly to counting, checking, picking, positioning, embossing, printing, gluing and labeling, right through to bag sealing and packaging dispatch, all further process steps are involved in the development and implementation of customer-specific special solutions. In addition to reliability, the smooth interaction of the individual components is crucial to achieving the highest possible system availability in your production process.

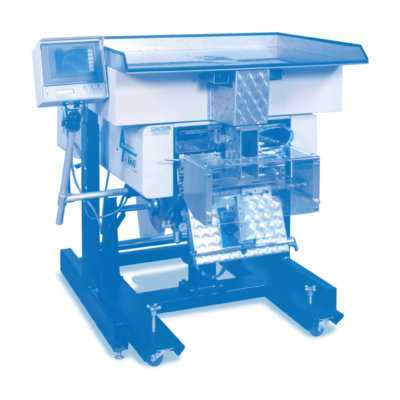

Friction feeder Whizzy Step Motor

The Whizzy Step Motor model is the most accessible model in the friction feeder family thanks to its retrofittable step motor and integrated electronics, which allow flexible integration into production and packaging lines. Flexible in terms of power, accessories and available sizes, the friction feeder is equipped with a stainless steel and die-cast aluminum structure, which makes it also suitable for use in the food and pharmaceutical industries. The friction feeder is very versatile and covers a wide range of products, such as coupons, leaflets, greeting cards, stickers, package inserts, smart cards, bags up to 3 mm thick or 8 mm with a special configuration. Like the other models in the series, the Whizzy Step Motor feeder is available in different widths and configurations: with horizontal or vertical terminal and in Whizzy 210 and Whizzy 350 widths, depending on the maximum size of the product. The friction feeder is also equipped with a display keyboard for advanced management of data exchange with the machine and the line.

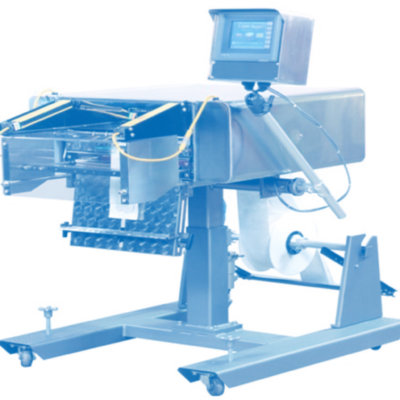

Automatic friction feeder

The Whizzy friction feeder is an automatic feeding machine for feeding and outputting flat products that can be placed at a selected point with the highest precision. The Whizzy series is the first choice for friction feeders in terms of performance, available auxiliary equipment and formats (lengths and designs) and is ideal for integration into OEM equipment and any packaging line where high speed and precision are required. The structure of this friction feeder is also made entirely of stainless steel, making it ideal for applications in food and pharmaceutical packaging lines.

The Whizzy friction feeder is very versatile and can handle a wide range of products, such as coupons, vouchers, leaflets, pre-folded brochures, envelopes, promotional and folded cards with thickness up to 3 mm in standard configuration or up to 8 mm in customized configuration. The Whizzy series of friction feeders is available in a wide range of widths and configurations: with horizontal or vertical dispensing units, widths Whizzy 110, Whizzy 210, Whizzy 350, depending on the format, with brushless motor, PLC electronics for advanced management of data exchange between the feeder and the packaging line. You can feed single products or in batches.

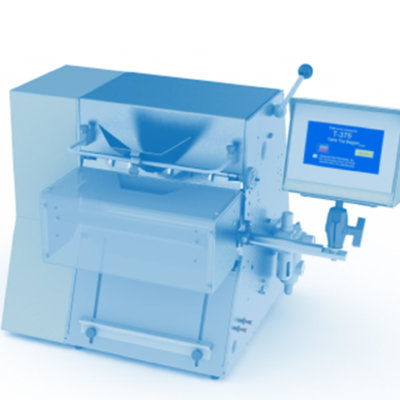

Friction feeder machine – versatile and reliable

Our friction feeders are ideal for separating, dispensing and counting all kinds of flat products such as package inserts, promotional brochures or loop labels for bottlenecks, etc. These can be easily fed to running or stopped products. Our machines convince by their easy operation and flexible use on existing production lines.

The Whizzy Step Motor is one of our most versatile automatic friction feeders. Retrofitted stepper motors and integrated circuits allow very agile integration into production and packaging lines. Multiple accessories and available sizes make this friction feeder a top performer. Automatic friction feeders are also extremely versatile and cover a wide range of products that can be processed. These include coupons, flyers, greeting cards, stickers, package inserts, etc. Like other friction feeders, the Whizzy Step Motor is available in a variety of sizes and styles. In addition, the friction feeder is equipped with an on-screen keyboard that enables easy data exchange between the production line and the friction feeder.

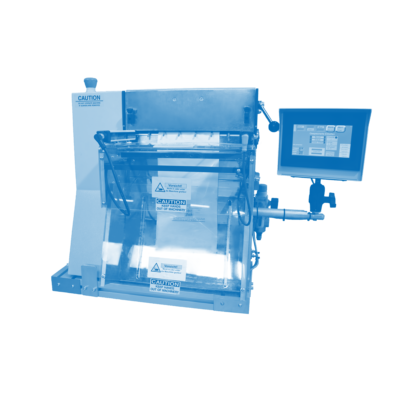

The Agile Friction Feeder is an innovative separator developed by Etipack for general mail, graphic arts and paper converting applications. This can be used for a wide range of products and is compatible with all standard paper gluers, labelers and inkjet printing systems. The agile 100/m/min friction feeder ensures high productivity and output. Independently driven rollers and belts allow for clean separation of loaded product. The Whizzy friction feeder for flat products is precise and versatile. This friction feeder uses the friction principle and feeds all types of flat products. Standard or customized output units allow easy integration of the friction feeder into a variety of production lines such as flow wrapping.